Foreword: Polyetherketoneketone (PEKK) is a semi-crystalline thermoplastic that is widely used in the additive manufacturing market. Both PEKK and PEEK belong to the PAEK family which well known in their excellent mechanical thermodynamic and chemical properties. PEKK is easier to print compare to PEEK, mainly because of the slower crystallization rate and lower melting point. However, since there are only few companies in the world produce it, it is still an expensive material compare to most of the 3D printing materials, which mainly used in demanding industries such as aerospace or oil and gas.

It is reported that Stratasys’ Antero 800NA material (a type of Polyetherketoneketone (PEKK)) has been certified by Boeing, which means that this material can be used in applications such as environmental control pipes. At present, 3D printing has been widely used in commercial aircraft. In the field of military aviation, it may be more likely to be used to modify and upgrade aircraft.

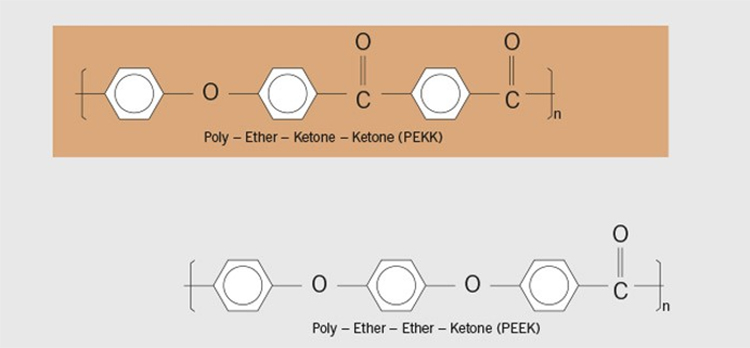

Molecular Structure of PEKK and PEEK

The composition of PEKK and PEEK are very similar, mainly made of ketones and ethers. The main difference of these two high performance materials is the ratio of ether/ketone: PEKK has more ketone bonds, which is more rigid than ether bonds, this increate the flexibility of the polymer chain, thereby increase the glass transition temperature( the temperature which polymer begin to soft) and the melting temperature. At the same time, the crystallization rate is reduced, this is the processing characteristic that is most crucial to 3D printing process; but do take note that this ratio is not the only difference.

In fact, the position of the ketone bond in its aromatic ring can be changed, this make it possible to change the melting point and crystallization rate.

For example:

1. A PEKK polymer with 60% linear segments and 40% kinked segments will melt at about 305°C, and the crystallization rate is very slow, thus it is usually called as “pseudo-amorphous”

2. The melting point of the similar polymer with 80% linear segments and 20% kinked segments is about 360°C, and the crystallization rate is similar to PEEK.

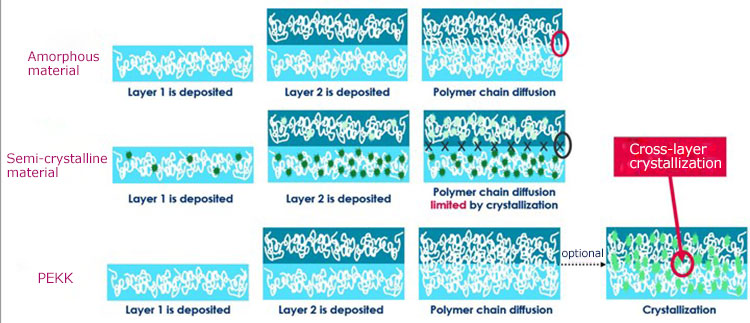

Polymer schematic

The PEKK filament launched by IEMAI 3D at this time, has a low crystallization rate, and can be deemed as an ‘amorphous’ polymer, which is less affected by cooling, which makes it better to adhere to the platform and avoids warping. This make it easier to print than PEEK. Together, it also has a better visual appearance and better wear and friction properties.

Application:

PEKK has an excellent abrasion resistance and chemical resistance. In fact, it can resist a variety of chemicals, for example most of the solvents and acid-base salt chemicals and refrigerants used in the automotive industry, and even a variety of alcohols, except concentrated sulfuric acid and dichloroacetic acid. The materials also have very good dielectric stability and insulation properties, which is the main advantage in the electronics field. Due to its resistance under high pressure and high temperature, PEKK is very popular in the aerospace and automotive sectors, as well as in the oil and gas industry. The material has a high ratio in strength/weight, which makes it to become the ideal solution for manufacture of key aviation parts, where weight reduction is the key to optimizing performance. In addition, carbon fibre reinforced PEKK composite material can also be used, thereby improving its rigidity and lightness.

IEMAI 3D is committed to the localization of high-performance materials in order to promote the industrialization of high-performance materials 3D printing applications. At present, PEEK, CF-PEEK, PEI 1010, PPSU and other high-performance wires had launched. The launch of PEKK this time is a stable product jointly launched by us and our partners after long-term research, development and testing.

↓↓Brand Introduction of IEMAI 3D↓↓

Imai Intelligent Technology Co. Ltd. is a high-tech enterprise in China focusing on 3D printing R&D and production. Its brand IEMAI 3D is a global industrial grade 3D printer brand, committed to provide users with the “All in one” 3D printing solution of multi material compatible issue. IEMAI 3D supports most of the thermoplastic materials in the 3D printing markets and assist the user to resolve the issue encounter during manufacturing, and all 3D printers and materials have contained CE and ROHS certification. We attach great importance to brand building and have obtained trademarks certificates from China, United Sates and the European Union. We pursue core technology research and development, and have obtained software copyrights, invention patents, utility model patents, appearance design patents, and the title of national high-tech enterprise. At present, our 3D printing solutions have been applied to aerospace, automotive, petrochemical, medical, dental and electronics manufacturing.