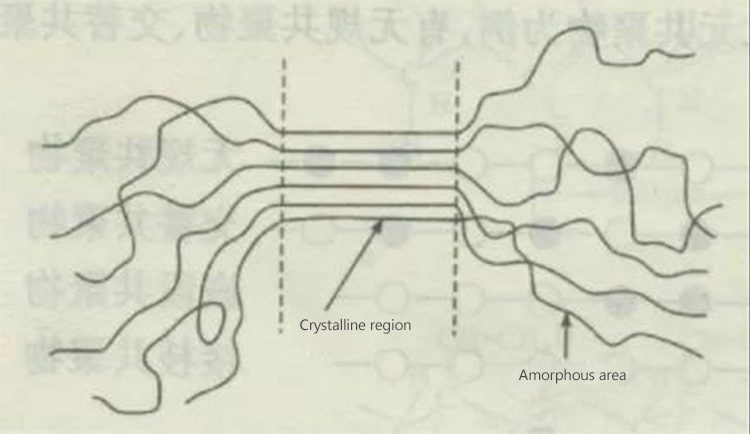

Polymer crystallization refers to an ordered state in which polymers chains are neatly arranged in a periodic structure. The regularly arranged area of the crystalline polymer is called the crystal area, the disordered area is called the amorphous area, and the percentage of the crystal area is called the crystallinity. In general, polymers with crystallinity over 80% are called crystalline polymers that is the crystalline polymer.

With the gradual deepening of the application of 3D printing technology to high molecular polymers, high temperature 3D Printer has played a critical role in industrial. At present, the mainstream high-temperature printers used a thermostatic chamber to achieve a crystalline state during printing process. However, due to the high crystallization temperature of portion polymers, very few printers can achieve a high degree of crystallization of such material during printing, and it is necessary to perform annealing treatment to recrystallize. Thus, is there any solution for this type of material to make it highly crystalline during printing process?

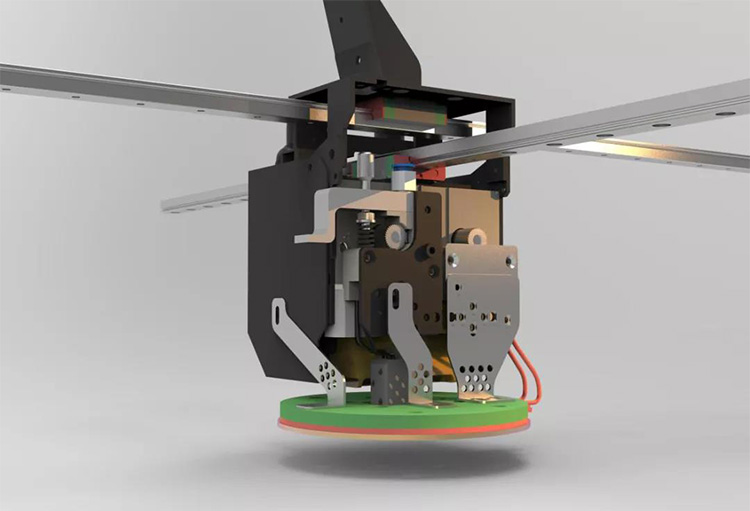

The optional heat radiation module of IEMAI 3D MAGIC-HT-PRO adopts regional heat radiation technology to draw the heat up to 220℃ accurately to the top layer of the parts and has a better effect on the surface quality and the treatment of small details, to achieve high-performance parts.

Five advantages of IEMAI 3D MAGIC-HT-PRO optional thermal radiation module solution (Using PEEK printing as an example):

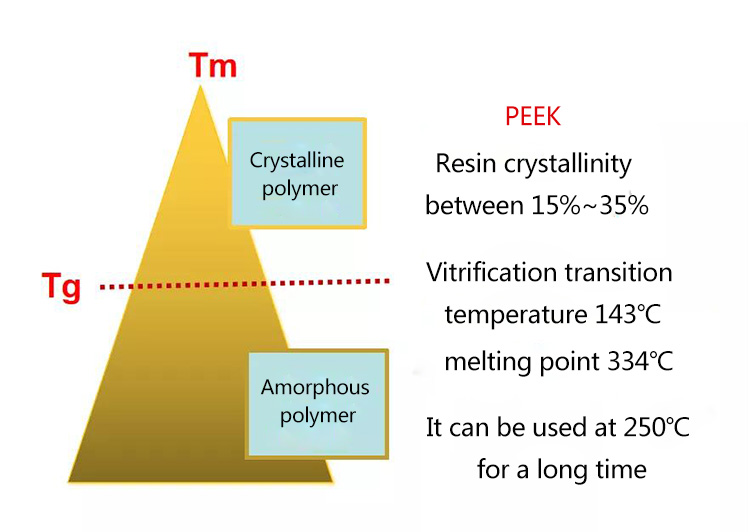

1. Obtain highly crystalline parts, with more excellent performance

When printing, the MAGIC-HT-PRO optional heat radiation module introduces heat that is higher than the crystallization temperature for the top layer of the part, and we will obtain a highly crystalline polymer.

In Optical, completely amorphous polymers are usually transparent (PEEK parts are bright yellow), and crystalline polymers are usually opaque (PEEK parts are white)

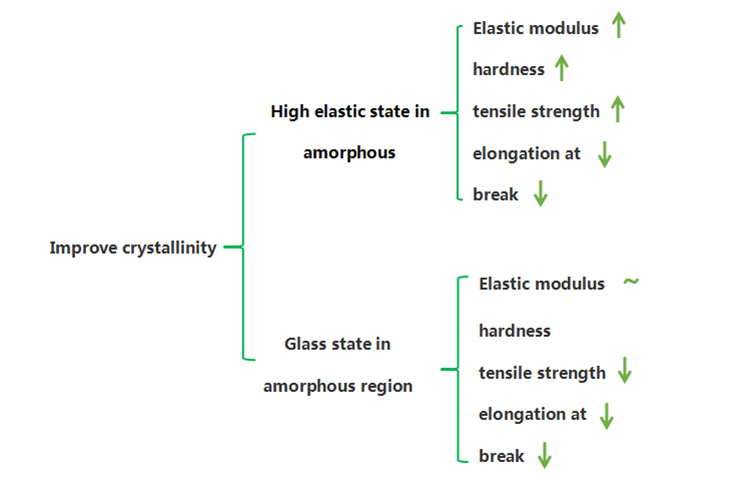

In terms of mechanical properties, highly crystallinity can be said as an advanced version of low crystallinity. The higher the crystallinity, the greater the density of the part, and the higher the crystallinity, the higher the tensile strength of the part. With the increase of crystallinity, the yield stress, strength, modulus and hardness of the polymer are all improved.

In addition, the highly crystalline polymer has unexpected performance in special situations.

- Increased in crystallinity, solvent resistance increases

- Increased in crystallinity, solubility decreases

- Increased in crystallinity, the permeability to gas and liquid decreases.

2.Well perform in surface quality and layer adhesion

During printing, introduces heat to the uppermost layer, and the lower layer gradually cools and solidifies. The overall part remains stable, and there is no deviation of the part due to the slight vibration of the nozzle. This performance is especially obvious when printing more precise parts. The top layer continues to receive heat, so that it can have a higher viscosity and bond with the material extruded by the nozzle, layer by layer, the overall adhesion of the part reaches the maximum of the material.

3. No annealing treatment required

The thermal radiation module continuously provides heat during printing, so that each layer of the part received the same amount of heat. After printing, each part of the part will reach a high degree of crystallinity, the colour is uniform, and the surface quality tends to be consistent. Therefore, the parts do not need to be annealed to avoid unpredictable changes due to high temperatures.

4. Flexible and precise heating, quickly adjust to any required conditions

The optional heat radiation module of MAGIC-HT-PRO only focus on precisely heating the top layer of the workpiece, and the heating area is small, which can be quickly adjusted to any required conditions. The area of the high-temperature area is small, which will not cause unnecessary loss to circuit boards, circuits and other components, and extend the service life of the equipment.

↓↓Brand Introduction of IEMAI 3D↓↓

Imai Intelligent Technology Co. Ltd. is a high-tech enterprise in China focusing on 3D printing R&D and production. Its brand IEMAI 3D is a global industrial grade 3D printer brand, committed to provide users with the “All in one” 3D printing solution of multi material compatible issue. IEMAI 3D supports most of the thermoplastic materials in the 3D printing markets and assist the user to resolve the issue encounter during manufacturing, and all 3D printers and materials have contained CE and ROHS certification. We attach great importance to brand building and have obtained trademarks certificates from China, United Sates and the European Union. We pursue core technology research and development, and have obtained software copyrights, invention patents, utility model patents, appearance design patents, and the title of national high-tech enterprise. At present, our 3D printing solutions have been applied to aerospace, automotive, petrochemical, medical, dental and electronics manufacturing.