Large-scale 3D printing is slow? IEMAI 3D has a way

The molding speed of large-scale 3D printers is one of the frequently criticized problems. When we print a model more than one meter, it often takes dozens of days of processing time, which is unacceptable for users and cannot reflect the advantages of 3D printing. In order to solve this issue, IEMAI 3D launched a large flow of 3D printing head. The amount of material throughput can reach up to 1kg/hour. It only took 52 hours to print a 175cm high mannequin.

Use a large flow print head to make the original scale model, which takes 52 hours

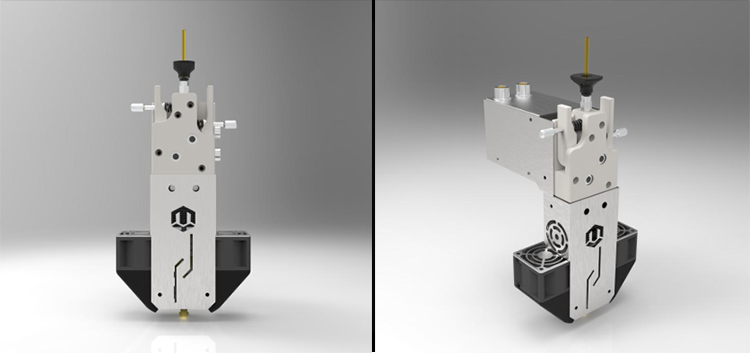

The high flow print head needs to use Ø2.85/3.0 mm filament and using the standard nozzle of Ø2.0 mm, which can print a layer thickness of more than 1mm, which is 5 times higher than the printing efficiency of the same model with a layer thickness of 0.2 mm. At the same time, we also provide nozzles with different specifications in the range of 0.4-2.5 mm to meet the needs of different layer resolutions

The highest printing temperature of the high-flow print head can reach up to 300 °C, and it is compatible with ABS,PC,PA,PLA,TPU,PETG,ASA,HIPS… and etcetera. The high-flow print head can be easily installed on our large-scale industrial printer which is YM-NT-1000 and YM-NT-750. Both industrial models are sealed and thermal insulated, its build plate can reach up to 120°C, when you are printing some engineering plastic, this temperature condition can provide a great help.

How to ensure that the material is dry when printing quickly? ?

We had also considered this problem and provided a solution

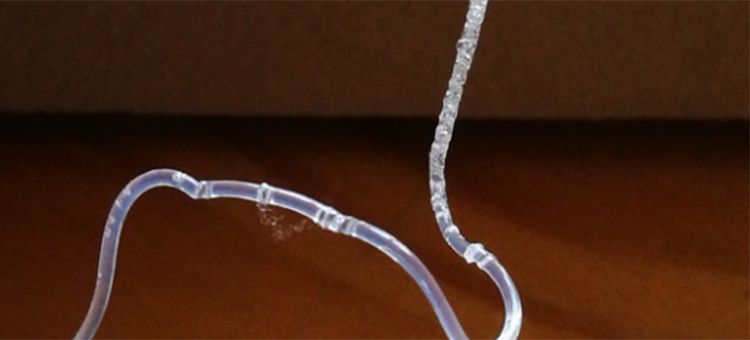

In the process of 3D printing, if the material absorbs moisture, a large sum of bubbles will be generated and affect the performance of the part. When we use high-flow printing, the bubbles will be obvious, which will affect the surface effect and performance of the whole part.

Therefore, we introduced a large-capacity filament heating and moisture proof cabinet to match the use of high-flow print head. The moisture proof cabinet can store up to 3 rolls of 5 Kg filament or 12 rolls of 1 Kg filament, compatible with filament of Ø1.75/2.85/3.0 mm, maximum heating temperature up to 80°C , the minimum humidity can be controlled up to 10% and at last it supports printing two filament at once.

Extremely high light transmittance shown when PC lampshade was printed while drying in process

High-flow print head and moisture-proof cabinet installed to industrial model

↓↓Brand Introduction of IEMAI 3D↓↓

Imai Intelligent Technology Co. Ltd. is a high-tech enterprise in China focusing on 3D printing R&D and production. Its brand IEMAI 3D is a global industrial grade 3D printer brand, committed to provide users with the “All in one” 3D printing solution of multi material compatible issue. IEMAI 3D supports most of the thermoplastic materials in the 3D printing markets and assist the user to resolve the issue encounter during manufacturing, and all 3D printers and materials have contained CE and ROHS certification. We attach great importance to brand building and have obtained trademarks certificates from China, United Sates and the European Union. We pursue core technology research and development, and have obtained software copyrights, invention patents, utility model patents, appearance design patents, and the title of national high-tech enterprise. At present, our 3D printing solutions have been applied to aerospace, automotive, petrochemical, medical, dental and electronics manufacturing.