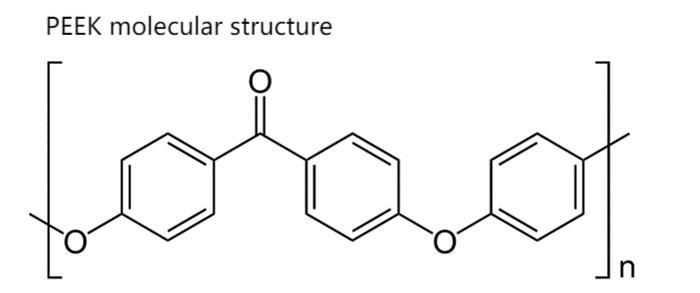

With the continuous development of 3D printing technology, different materials have their own capabilities in different application fields.PEEK stands out among many materials with its excellent high-performance characteristics, and has been widely used and recognized in the industry.Because of the complex structure of PEEK , Under different printing conditions, different printing effects will be presented, and the performance will also be different.So how to choose a better peek printing material during the printing process?

IEMAI3D’s PEEK 3d printing filament

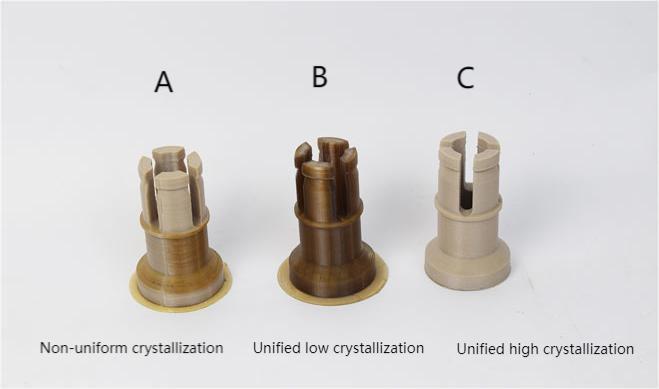

In order to explore the best performance state of PEEK prints, we selected three PEEK materials for testing, and controlled different variables from printing temperature, printing rate, chamber temperature, hot bed temperature, etc. final conclusion:

The reason why PEEK materials appear in the above three different colors is mainly because of their different degrees of crystallization uniformity, which causes the printed parts to be affected from three aspects: surface color uniformity/interlayer bonding/surface texture:

- Surface appearance, when the crystallinity is uniform, the surface of the printed part is dark brown and slightly glossy, when it is off-white matte texture, it is uniform and high crystallinity, and when the crystallinity is not uniform, the above two colors will also appear. Transition color between two colors.

- It also has an impact on mechanical properties. Compared with non-uniform crystallinity, the printed parts with uniform crystallinity have better bearing capacity when applying force in the z-axis direction

- Surface roughness, uniform crystallinity, compared with non-uniform crystallinity, the surface is smoother, the crystallinity is not uniform, and the surface appears irregular rough texture.

Analysis of the comprehensive performance of the printed parts: C>B>A

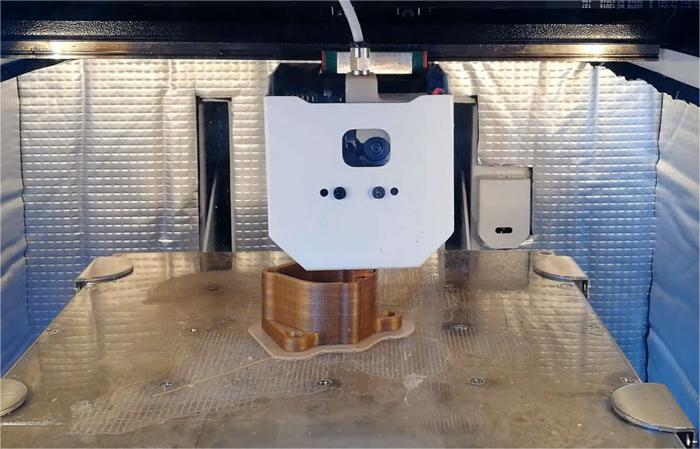

To sum up, IEMAI’s material has a smaller crystallization window, which makes it easier to achieve the unity of crystallization, and can better reflect the application performance in use.

1-When your printer does not reach the crystallization temperature, the parts tend to show uniform non crystallization.

2-When your printer reaches the crystallization temperature, the parts tend to present uniform crystallization.