1. Introduction Of Carbon Fiber PEEK 3D Printing Material.

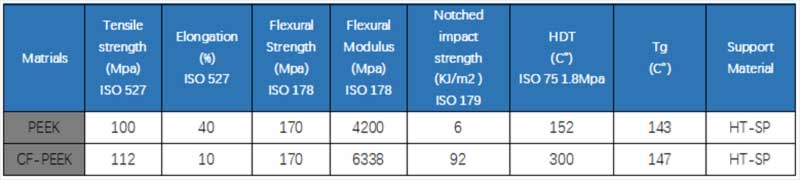

Polyether ether ketone (PEEK) is a semi-crystalline polymer material, belonging to a class of polyaryl ether ketone (PAEK) polymer, which has excellent comprehensive properties and is recognized as one of the highest performance thermoplastics in the world.

The carbon fiber reinforced polyether ether ketone composites can be made by filling modification of polyether ether ketone with carbon fiber. It has all the capabilities of PEEK and further improves its overall performance to meet the needs of specific application fields.

Carbon fiber reinforced polyether ether ketone (CF-PEEK) is a composite material with polyether ether ketone (PEEK) resin as the matrix and carbon fiber as the reinforced material. The main characteristics are high temperature resistance, corrosion resistance, fatigue resistance, easy processing, stability and good mechanical properties.

It is insoluble in any strong acid or alkali except concentrated sulfuric acid. It can be used at high temperature for a long time and can adapt to extreme environment.

At present, the research of carbon fiber reinforced polyether ketone mainly consists of short carbon fiber reinforced and continuous carbon fiber reinforced.

The fiber retention length of short carbon fiber is less than 1 mm (IEMAI carbon fiber diameter is 0.03mm-0.06mm), which is made of continuous carbon fiber by machine cutting, and the basic performance depends on the continuous carbon fiber performance. PEEK matrix can be filled into composite materials, which is a relatively simple process of application. After testing by the technical team of IEMAI, the proportion of carbon fiber is relatively stable between 10-20%.

The theoretical fiber retention length of continuous carbon fiber is consistent with the final product size, and the comprehensive performance is better and the stability is stronger, so it is a good experimental material in the cutting-edge field. Because of the difficulty of production and the problem of mass production efficiency, the application of continuous carbon fiber technology is relatively small.

At present, the short carbon fiber reinforcement technology of IEMAI has been very mature, and is in the development process from short carbon fiber reinforcement to continuous carbon fiber reinforcement technology. Continuous carbon fiber reinforcement is the main development direction of IEMAI.

2. The Application Of Carbon Fiber PEEK 3D Printing Material.

Carbon fiber reinforced polyether ether ketone (CFRP) has excellent comprehensive properties and is the most ideal metal substitute nowadays. It is mainly used in aerospace, machinery, automobile manufacturing, petroleum industry and medical fields.

The use of 3D printing technology in the oil industry can make oil extraction more efficient and cost effective.

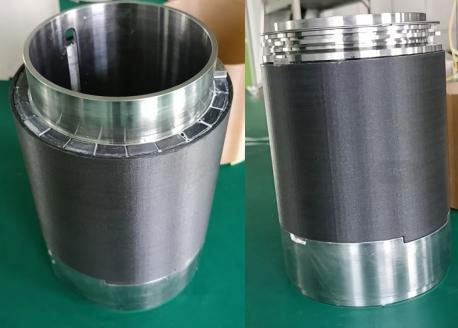

A manufacturer of oil exploitation equipment found IEMAI in early 2022, hoping to 3D print a resolver housing, an important component in underground drilling equipment.

In order to ensure the stable operation of the rotary transformer in the underground high temperature and high pressure environment and meet the lightweight requirements, after the evaluation and cost analysis of the technical team of IEMAI, the high-temperature 3D printer MAGIC-HT-M was finally selected to print CF-PEEK carbon fiber reinforcement material to produce the resolver housing.

In July 2022, the rotary transformer with CF-PEEK housing printed by IEMAI was tested for underground drilling in Bayannur, Inner Mongolia. After repeated comparative tests, it was verified that the 3D printed housing fully met the requirements of underground drilling.

Mr. Yang, the customer, said that the production of carbon fiber reinforced PEEK resolver housing by 3D printing would reduce the cost by at least 50% compared with the subtractive manufacturing.

The SmarTech Analysis, a leading provider of industry analysis and market forecast data for the additive manufacturing industry, expects polymer 3D printing to generate up to $11.7 billion in revenue in 2020, including sales generated from polymer additive manufacturing equipment and all related material lines.

At present, FDM technology is the mainstream method for printing carbon fiber reinforced polyether ketone materials.

Carbon fiber reinforced polyether ether ketone is a demanding 3D printing material due to its high melting point and semi-crystalline properties.

Compared to most other thermoplastics, CF-PEEK needs to be extruded at relatively high temperatures.

For an excellent CF-PEEK 3D printer, the printing temperature should reach more than 400°C, and a enclosed hot chamber is required to maintain constant temperature during the printing process, so as to effectively avoid warping and deformation of model, and improve the surface quality of printed part.

IEMAI, an industrial-grade 3D printing brand, has launched a series of high-temperature 3D printers designed for high-performance polymers such as carbon fiber reinforced materials. The IEMAI high temperature 3D printers are equipped with the powerful self-developed slicing software of IEMAI 3D EXPERT. The nozzle with high wear resistance is specially designed to optimize the wear problem of the nozzle caused by carbon fiber reinforced materials. In addition, for the fluidity of CF-PEEK, the IEMAI high temperature 3D printers adopt a double gear extrusion feeding system to make the printing speed faster and smoother.

IEMAI High Temperature 3D printer Series

IEMAI High Temperature 3D printer Series

3. Summary

As a high-performance composite polymer, carbon fiber reinforced polyether ether ketone is limited to only the most demanding applications due to its complex production process and high price. With the continuous in-depth research, carbon fiber reinforced polyether ether ketone will definitely be more widely recognized and applied in various fields.