Designer: Huang Guoyu

Graduated from Central Academy of Fine Arts (CAFA), Class of 2021, studying at CAFA Industrialization Research Studio, now lives in Beijing.

Title of work: Trans-dimensional Printing

Project Supervisor: Yang Yuan

Graduation show

In the field of furniture production, the mass production mode brought by the industrial revolution has brought a variety of homogeneous products into the common home, now in the era of big data and digitalization, what will be the corresponding production mode for a more personalized and intelligent mode?

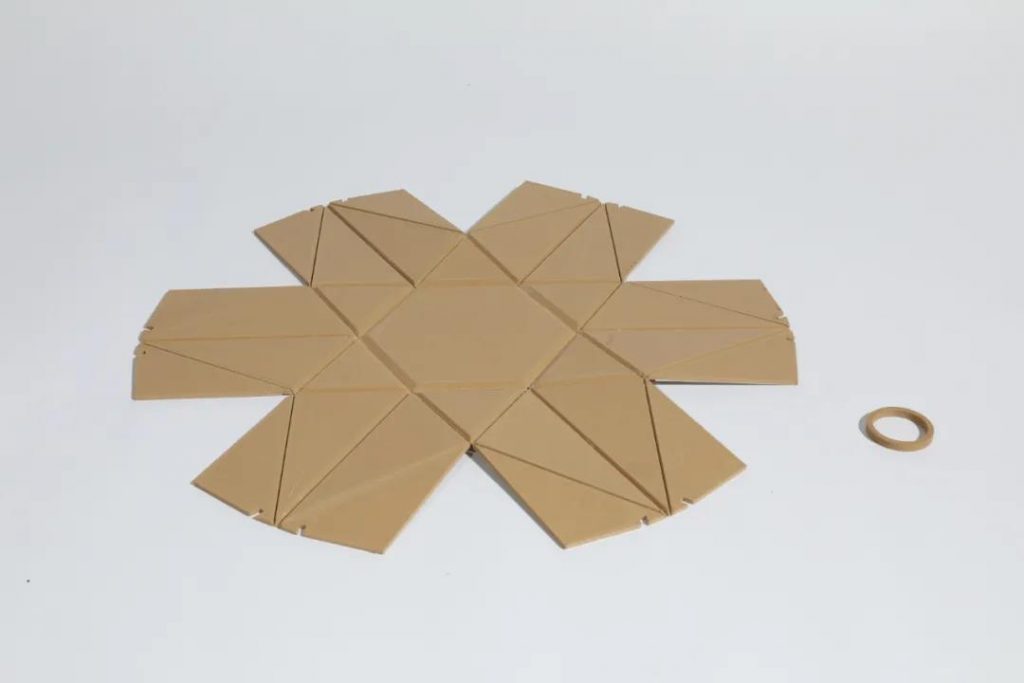

The designer’s series of works mainly aims to optimize the production of parametric products and explore new manufacturing methods, using the parametric plug-in Crane as a tool for folding form generation, using “3D printing on elastic fabric to generate self-assembled folding products” and “through multi-material integrated printing to complete The multi-material 3D printing of “flat folding solution” is the technical means to realize the dimensional transformation of products from two-dimensional production to three-dimensional molding, which also provides a more perfect production method for the production of parametric personalized design solutions and provides a direction for home design to connect with intelligent manufacturing.

A variety of 3D printing materials in one print to generate folding products

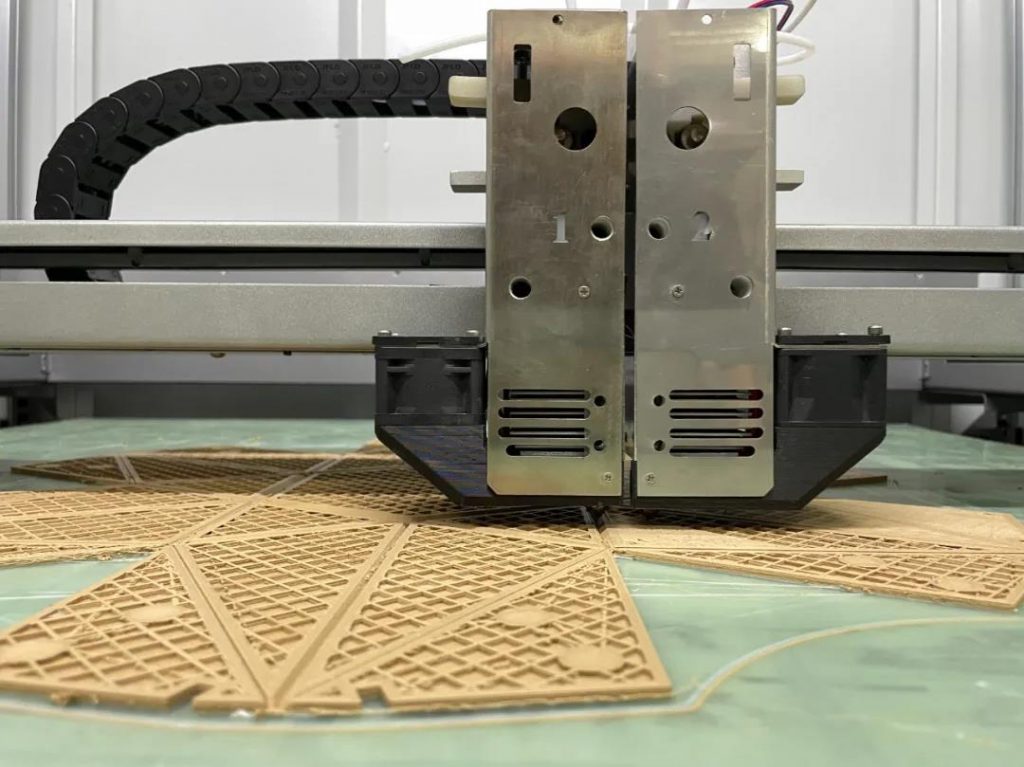

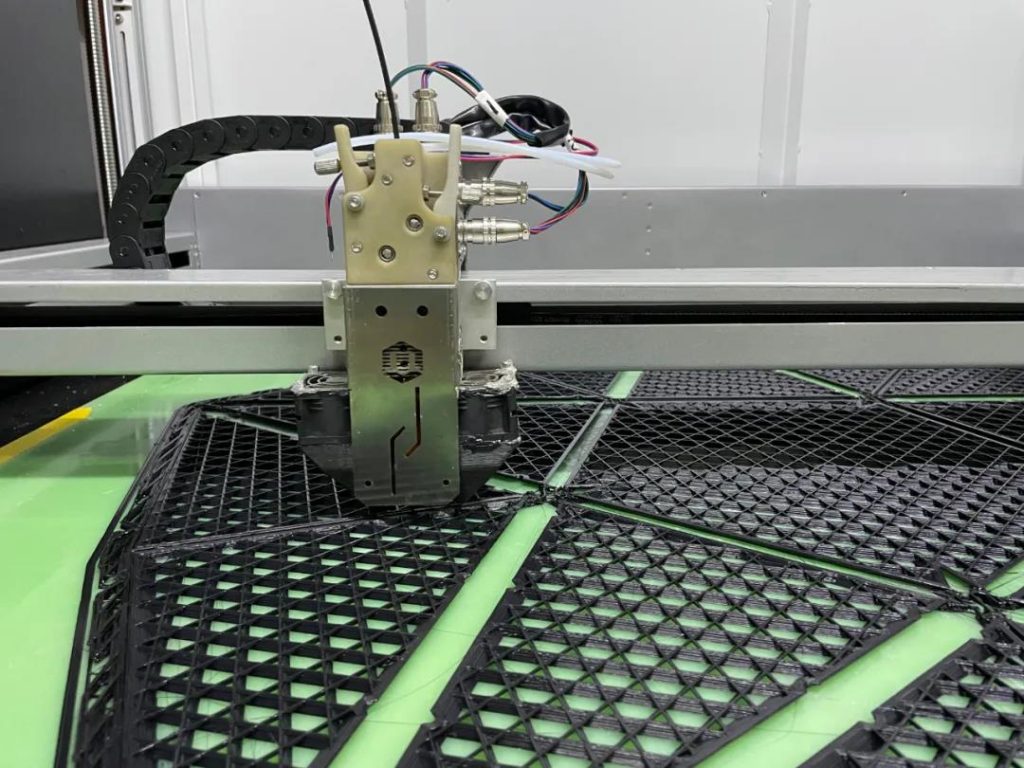

Multiple 3D printing materials in one print to generate folded products dual nozzle dual material 3D printing

Equipment used: IEMAI 3D printer YM-NT-750

Material used: Hard material PLA & wood plastic PLA & soft material TPU 95A, sponsored by Polymaker

Print size: 470mm*450mm*3mm *2pcs

Print time: 11 hours *2pcs

Dual Printhead Dual (Wood Plastic + TPU)

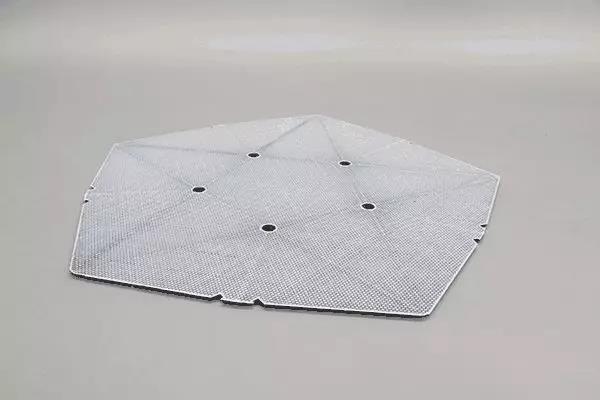

Flat display (Wood Plastic + TPU)

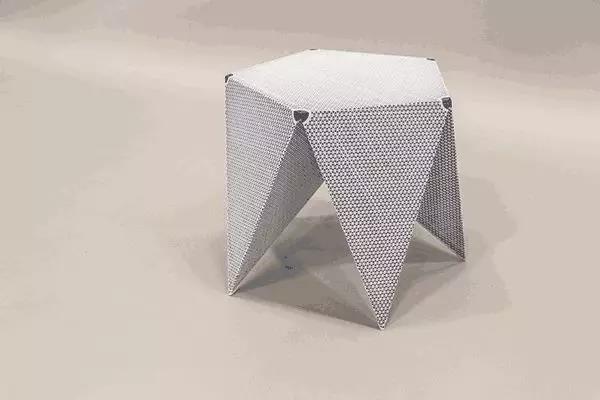

Fold display (Wood Plastic + TPU)

Flat display (PLA Silver + TPU)

Fold display (PLA Silver + TPU)

Single-jet dual-material 3D printing

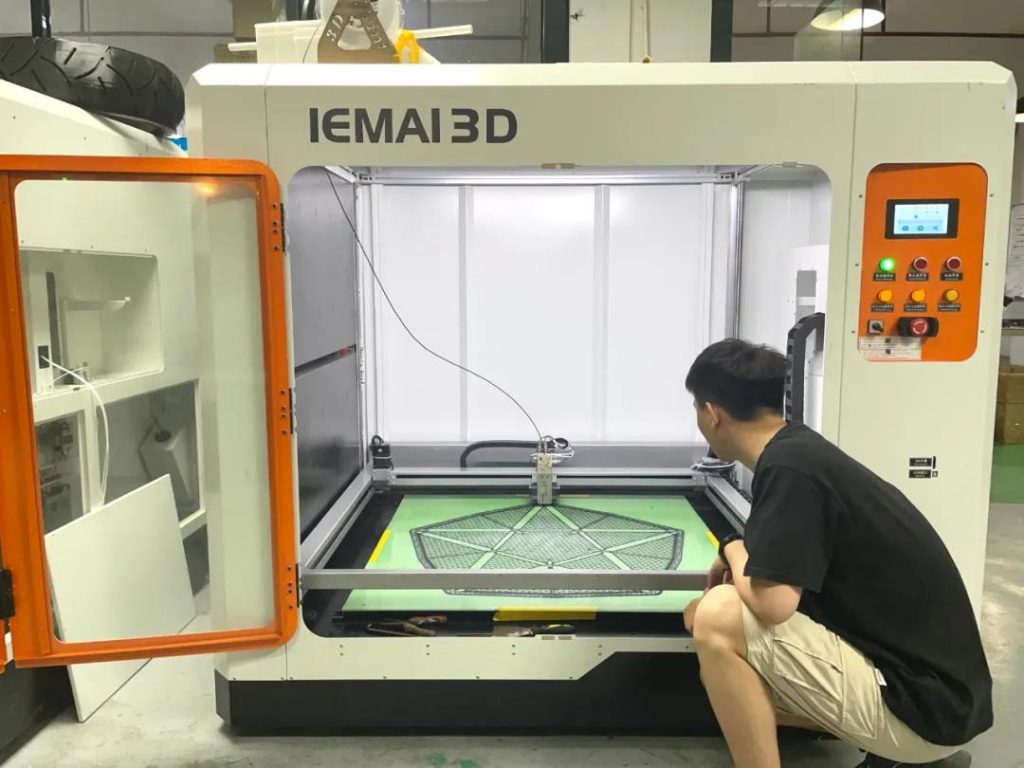

Equipment used: IEMAI 3D printer YM-NT-1000

Material used: Hard material PLA & soft material TPU 90A, sponsored by Polymaker

Print size: 900mm*870mm*10mm

Printing time: 46 hours

Large Flow Nozzle Printing 2.85mm Diameter Filament

Flat Display (PLA + TPU)

Fold Display (PLA+ TPU)

Designer Huang Guoyu at IEMAI3D

The rapid development trend of digital design, we can intervene through digital, parametric and intelligent ways to bring some disruption to the traditional furniture production industry.

The way of multi-material 3D printing not only optimizes the production of parametric products and explores a new type of 3D printing, but also provides a more perfect way for personalized design solutions, and even provides direction for home design to dovetail with intelligent manufacturing.

↓↓ Polymaker Brand Introduction↓↓

Polymaker is a high-tech enterprise focusing on 3D printing materials, committed to promoting the in-depth application of 3D printing technology in various industries with leading technology, high-quality products and meticulous and in-depth services. The products are widely used by customers around the world in many fields such as automotive, aerospace, industrial manufacturing, medical, and consumer.

↓↓Brand Introduction of IEMAI 3D↓↓

Imai Intelligent Technology Co. Ltd. is a high-tech enterprise in China focusing on 3D printing R&D and production. Its brand IEMAI 3D is a global industrial grade 3D printer brand, committed to provide users with the “All in one” 3D printing solution of multi material compatible issue. IEMAI 3D supports most of the thermoplastic materials in the 3D printing markets and assist the user to resolve the issue encounter during manufacturing, and all 3D printers and materials have contained CE and ROHS certification. We attach great importance to brand building and have obtained trademarks certificates from China, United Sates and the European Union. We pursue core technology research and development, and have obtained software copyrights, invention patents, utility model patents, appearance design patents, and the title of national high-tech enterprise. At present, our 3D printing solutions have been applied to aerospace, automotive, petrochemical, medical, dental and electronics manufacturing.