Project Description

3D Printing technology is changing the ways retail is marketed

3D printing technology is changing the way of marketing in the retail business, as well as the way of creating advertisements and setting up themed environment. Using large 3D printer, one can produce super large objects for retail, stage, display, event and architectural design, which can be of any size and shapes with being restricted by traditional methods. Most importantly, 3D printing technology offers the opportunity to create an eye-catching expression for public.

It took only 52 hours to print this Mannequin using the large machine from IEMAI 3D

Advantages of 3D printing technology to change marketing mode

Reduce assembly: The use of 3D printing technology can combine the models as much as possible during modelling, which reduces the need of bonding or mechanical fixing; this will minimize the needed of pre/post-processing to its greatest extend. The ability to manufacture large objects at once, can simplify the manufacturing process and save plenty of time.

Functional type: 3D printing technology provides the possibility of visualization, technicalization and rapid iteration of design. You can also control the material and make it to have different performances, for example rainbow colour, colour change when exposed to light or temperature change, shading/ Light and etcetera.

Expand creativity: larger models can express more details. For example, several artists have integrated 3D printing into their projects to produces over 20 feet long, make dinosaur sculptures with wonderful skin details, print full-size human busts, spaceship simulators and functional robots. The possibility for creating new project are endless.

↓↓Brand Introduction of IEMAI 3D↓↓

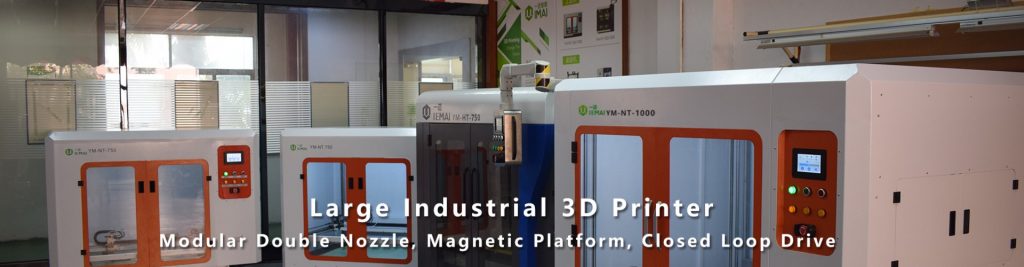

Imai Intelligent Technology Co. Ltd. is a high-tech enterprise in China focusing on 3D printing R&D and production. Its brand IEMAI 3D is a global industrial grade 3D printer brand, committed to provide users with the “All in one” 3D printing solution of multi material compatible issue. IEMAI 3D supports most of the thermoplastic materials in the 3D printing markets and assist the user to resolve the issue encounter during manufacturing, and all 3D printers and materials have contained CE and ROHS certification. We attach great importance to brand building and have obtained trademarks certificates from China, United Sates and the European Union. We pursue core technology research and development, and have obtained software copyrights, invention patents, utility model patents, appearance design patents, and the title of national high-tech enterprise. At present, our 3D printing solutions have been applied to aerospace, automotive, petrochemical, medical, dental and electronics manufacturing.

Project Details

- Printing Sizes: 70 cm x 16 cm x 175 cm

- Total Cost : $210

- Prototype:Mannequin

- Filament Used: 15 KG

- Time Spend: 52 Hours

Printer & Material

- Printer Used: YM-NT-1000

- Material Used:PLA