With over 50 years of service experience, AIS is a Federal Aviation Administration-certified maintenance organization, ensuring the highest standards of quality, reliability, and innovation for business aviation customers.

Image | Banner on the AIS Aircraft Interiors Service Team website

Image | Banner on the AIS Aircraft Interiors Service Team website

Previously, the AIS team received a custom cabin maintenance order related to Ultem™ 9085 printing for aircraft sun visors. Due to the flame-retardant and temperature-resistant properties of Ultem™ 9085, its printing required a large-format, high-temperature 3D printer. The AIS team contacted IEMAI3D for assistance. After technical discussions and sample verification, the MAGIC-HT-MAX was ultimately selected as the production tool.

Image | Interior of the cabin requiring repair

Image | Interior of the cabin requiring repair

The MAGIC-HT-MAX is an industrial-grade 3D printer with printing temperatures up to 500°C, platform temperatures up to 200°C, and cavity temperatures up to 150°C. It is compatible with printing large-size parts made of high-performance materials such as Ultem™ 9085/1010, PEEK, and PEKK. Note: Ultem™ is a proprietary trademark of Sabic Corporation, generally used to represent its PEI specialty engineering materials.

Ultem™ 9085 possesses excellent flame retardancy and low smoke toxicity, which are primary requirements in the aerospace industry, especially for passenger aircraft interiors. It meets the most stringent aerospace standards, passing multiple aerospace flame retardancy standards such as FAR 25.853, which are mandatory regulations for aircraft interior materials issued by the US Federal Aviation Administration. Furthermore, its Limiting Oxygen Index (LOI) reaches Ul94 V-0, meaning it is extremely difficult to ignite in normal air and self-extinguishes upon removal of an open flame.

Image | MAGIC-HT-MAX on-site printing

Image | MAGIC-HT-MAX on-site printing

MAGIC-HT-MAX has created optimal temperature and dedicated process conditions to adapt to 3D printing with Ultem™ 9085, and developed a dedicated 3D printing extruder to significantly enhance interlayer bonding, resulting in excellent surface finish and mechanical properties. Printed parts exhibit high tensile strength and flexural modulus, capable of withstanding mechanical stresses such as vibrations and pressure changes during flight. Unlike many brittle engineering plastics, Ultem™ 9085 is not easily broken upon impact, demonstrating excellent durability.

Image | Schematic diagram of a sun visor (from the internet)

Image | Schematic diagram of a sun visor (from the internet)

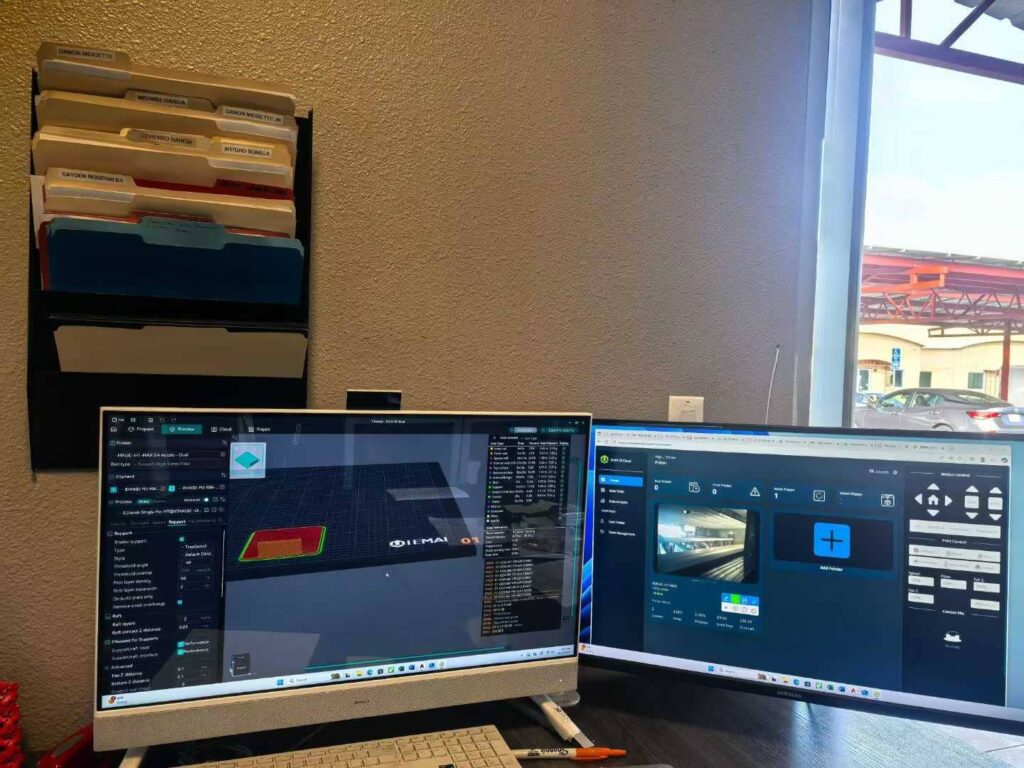

IEMAI has integrated a dedicated process package for the PEI 9085 into its slicing software, IEMAI 3D Slicer, which, when paired with a dedicated 3D printing extruder, enhances the printing results of the Ultem™ 9085. Combined with its cloud platform, IEMAI 3D Cloud, it enables remote management and monitoring. Currently, its AI visual recognition and detection model is undergoing internal testing and training, aiming to provide users with more intelligent management tools.

Image | IEMAI 3D Slicer and Cloud

Image | IEMAI 3D Slicer and Cloud

The AIS team stated, “We are very grateful to the Yimai team for their professional technical support. We believe this is a very worthwhile investment. Providing additional value to users through additive manufacturing will make our team’s services unique, allowing us to quickly recoup our investment costs and generate additional profits. The digital management platform also frees up our time and labor, thus unleashing the charm of additive manufacturing.”

Photo | AIS and IEMAI team

Photo | AIS and IEMAI team