Preface: On the journey of exploring the sky and the universe, size is often the boundary of creativity, and time is the enemy of development. The School of Aerospace Engineering at the University of Science Malaysia (USM), a top tier institution dedicated to cultivating future aerospace engineers, is arming itself with cutting-edge technology. They have recently introduced a large-sized industrial grade FDM 3D printer, which, with its large molding space, extensive material compatibility, significantly improved printing speed, and digital cloud platform intelligent management, is completely changing students’ design thinking, accelerating the scientific research process, and injecting surging power into aerospace prototype manufacturing!

1、 Challenge: When ‘Big Dream’ Meets’ Small Box ‘

For the USM School of Aerospace Engineering, traditional desktop level 3D printers are no longer sufficient to meet the demand. Whether it’s verifying 1:1 scale drone wings, satellite support structures, or complex rocket engine component prototypes, students often face embarrassment:

Helpless disassembly: Large components are forced to be split and printed, and later splicing is time-consuming and labor-intensive, affecting structural strength and accuracy.

Long wait: slow printing speed, complex models often take tens of hours, seriously slowing down the R&D iteration cycle.

Limited materials: Engineering grade high-performance materials (such as high temperature resistant and high-strength composite materials) have limited support and cannot truly simulate the working conditions of aviation components.

Traditional management: When multiple equipments, users, and projects are running in parallel, management is chaotic and inefficient.

The college urgently needs an industrial grade manufacturing platform that can “accommodate” grand ideas, “outperform” research and development pace, “withstand” strict requirements, and “manage” complex tasks well.

2、 Solution: IEMAI FDM Industrial Grade “Smart Manufacturing Equipment”

After strict screening and evaluation, USM ultimately chose the YM-NT-1200, a large-format industrial grade FDM 3D printer from IEMAI. With 4 core advantages, it accurately solves user pain points:

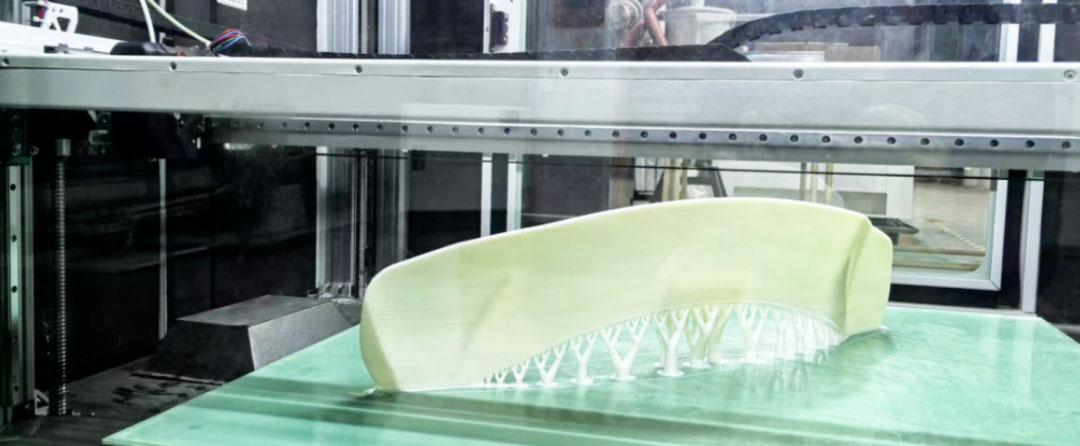

1. 【 The super large molding space allows sparkling of creativity 】

With a huge printing chamber of up to 1200mm x 1200mm x 1200mm, students and researchers can print complex large components such as small drone bodies, large aircraft intake pipes, satellite structural frames, etc. in one go, completely breaking free from the constraints of “splicing”, ensuring the integrity and structural strength of the design, and greatly improving the authenticity and reliability of prototype verification.

2. 【 Wide Material Compatibility – Unlocking Aviation Grade Performance 】

With a powerful temperature control system and extrusion design, a printing temperature of 300 ℃, a hot bed temperature of 120 ℃, a chamber temperature of 60 ℃, and a material compartment temperature, the college is perfectly compatible with high-performance engineering plastics such as carbon fiber/glass fiber reinforced composite materials. This allows the college to simulate the actual working conditions of aerospace devices (high temperature, high pressure, high load), conduct more challenging material performance testing and functional verification, and greatly promote laboratory achievements to practical applications. Students can also have access to cutting-edge materials in the industry, enhancing their core competitiveness.

CF-PAHT Printed Part

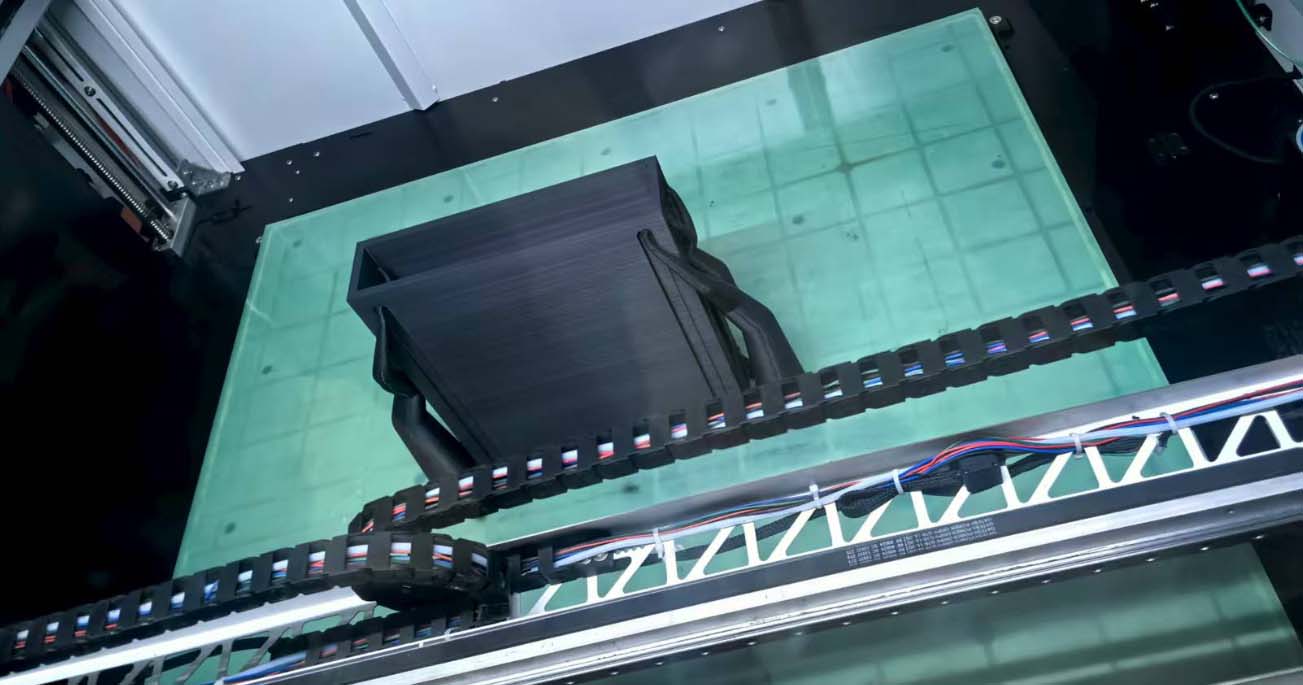

3. 【 Ultra-fast and efficient printing – pressing the R&D “accelerator” 】

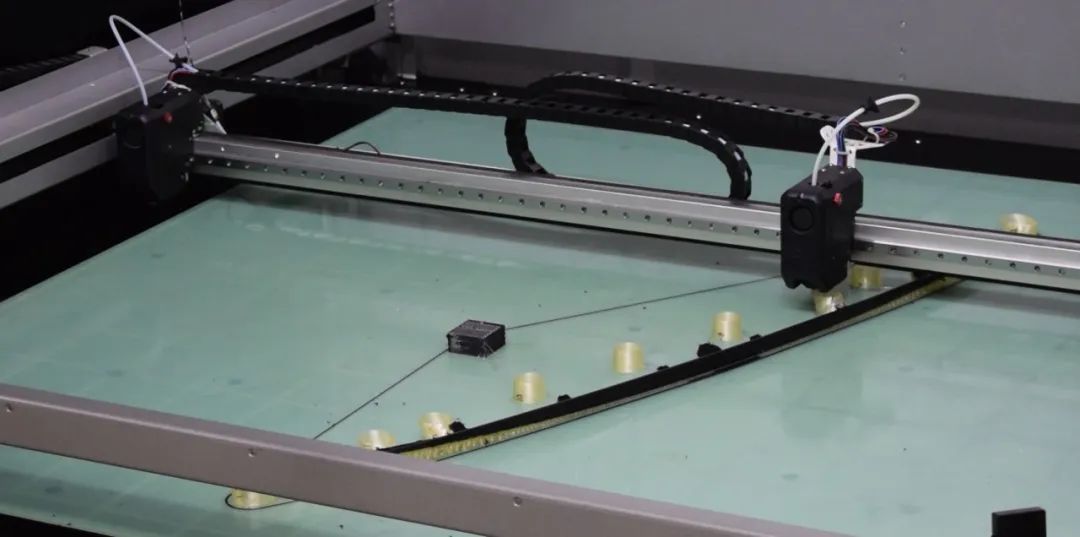

The optimized motion system, efficient heating and cooling design, combined with intelligent algorithms, and IDEX’s dual head mirror printing achieve printing speeds far exceeding traditional devices. Significantly reducing the prototype production cycle, improving the iteration speed of student projects, and enabling the rapid advancement of key validation stages in teaching research projects. Designing on the same day and verifying the next day has become possible, greatly unleashing the potential for innovation.

IDEX Dual Head Mirror Printing Process

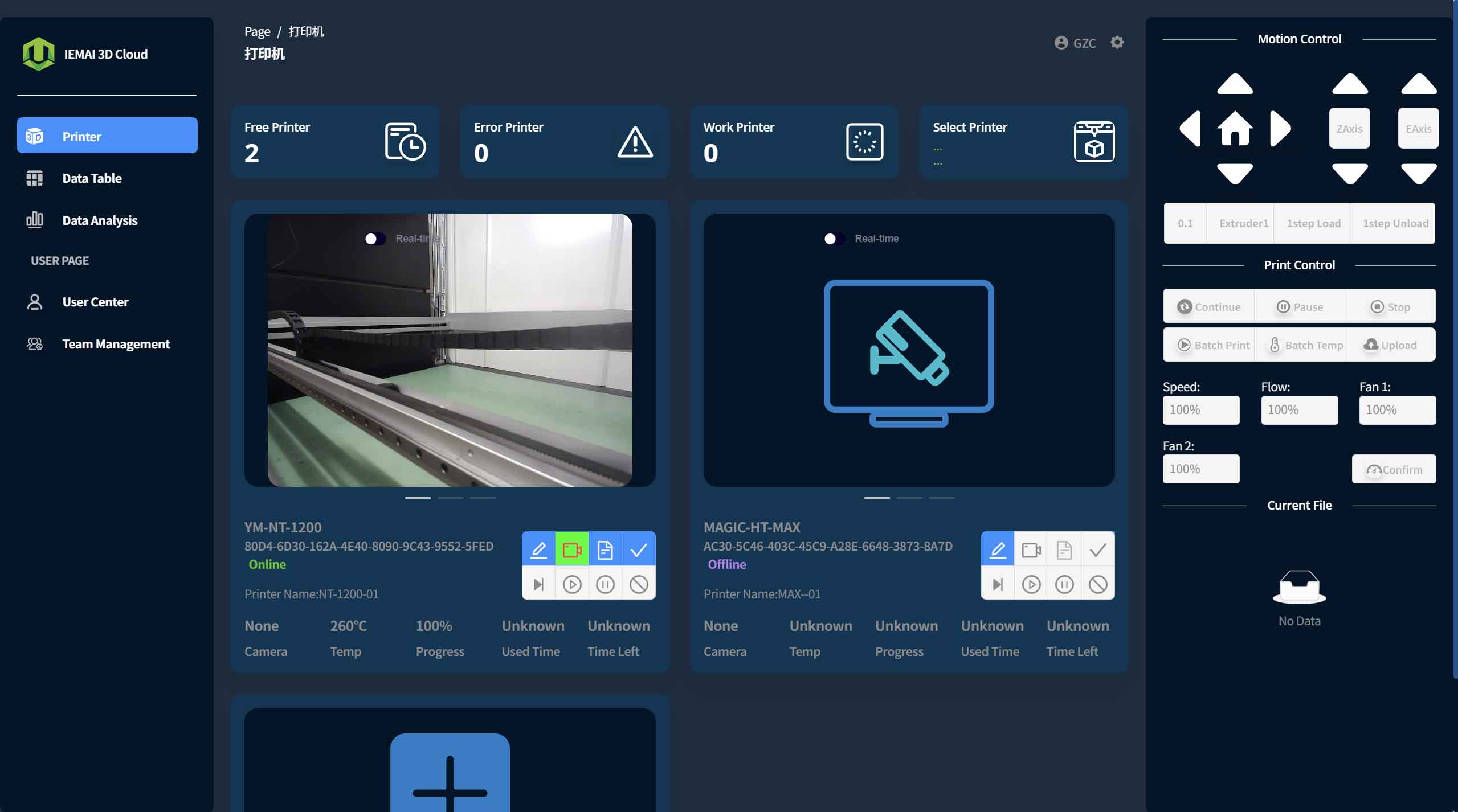

4. 【 Cloud intelligent platform – allowing manufacturing to be controlled in the palm of your hand 】

A deeply integrated cloud platform that provides one-stop intelligent services such as remote monitoring, task management, consumables management, data management, and AI visual recognition. Created a more manageable platform for professors/administrators, allowing them to view the status and printing progress of multiple devices in real-time on their mobile phones/computers regardless of their location. Monthly/quarterly/annual data analysis enables efficient and transparent laboratory management. Operators/students can submit printing tasks anytime and anywhere, eliminating tedious local operations.

IEMAI Cloud Platform Management Interface

3、 Application Scenario: Empowering Versatile Educators and Researchers

This industrial grade printer has quickly integrated into the USM School of Aerospace Engineering and is active in multiple key areas:

Teaching practice: design, manufacture, and testing of large-scale course projects for key components of aircraft/rockets/satellites for undergraduate or graduate students.

R&D: Provide fast and reliable manufacturing support for cutting-edge topics such as lightweight structural research, development of new thermal management systems, and advanced propulsion system prototypes.

Competition support: Assist student teams in efficiently producing large-scale and high-performance entries for drone or rocket design competitions.

Industry academia cooperation: providing high-quality prototype parts for collaborative projects with the industry, accelerating technology transformation.

4、 User Voice: Recognition from USM School of Aerospace Engineering.

“This large-sized printer from IEMAI has completely changed the rules of our game!” – Mr. Hafiz, Laboratory Manager of the School of Aerospace Engineering. “It used to be a nightmare for large-sized components, but now it has become so simple and efficient. What surprises us the most is its material compatibility and cloud platform intelligent management. Students can boldly try more complex aerospace grade materials, and teachers can easily manage the entire printing laboratory. It is not only a equipment, but also a strategic partner for us to cultivate future aerospace engineers and accelerate innovation.

User Review Video

Dongguan Imai Intelligent Technology Co., Ltd is a high-tech enterprise in China focusing on 3D printing R&D and production. Its brand IEMAI 3D is a global industrial grade 3D printer brand, committed to provide users with the “All in one” 3D printing solution of multi material compatible issue. IEMAI 3D supports most of the thermoplastic materials in the 3D printing markets and assist the user to resolve the issue encounter during manufacturing, and all 3D printers and materials have achieved CE and ROHS certification. We attach great importance to brand building and have obtained trademarks certificates from China, United Sates and the European Union. We pursue core technology research and development, and have obtained software copyrights, invention patents, utility model patents, appearance design patents, and the title of national high-tech enterprise. At present, our 3D printing solutions have been applied to aerospace, automotive, petrochemical, medical and electronics manufacturing.