The Three Gorges Reservoir Area is a vital water resource and ecological barrier for China, with its water quality directly impacting drinking water safety and ecological health in the middle and lower Yangtze River Basin. Key activities such as daily cleaning, subsidence area management, and cross-regional cooperation are essential for maintaining water ecological stability and maximizing the comprehensive benefits of the Three Gorges Project—including power generation, shipping, and flood control. Environmental governance in the reservoir area goes beyond simple waste retrieval; it involves coordinated regional efforts, judicial safeguards, technological innovation, and ecological restoration aimed at promoting green development. These initiatives help protect the Yangtze’s clean water and support the sustainable growth of the Yangtze River Economic Belt.

From 2024 to early 2025, cleanup efforts have removed tens of thousands of tons of floating debris, subsidence zone waste, and solid waste. Notable achievements include: Wanzhou District clearing over 3,900 tons of floating garbage since September 2024, underscoring its critical role as a core zone; Chongqing and Hubei judicial authorities collaborating to remove 122,000 tons of coastal solid waste, demonstrating the importance of legal mechanisms in large-scale environmental management; Targeted actions, such as remediation in the Chongqing subsidence area, effectively addressing specific types of waste in short timeframes.

In the 2024 clean-up campaign, an innovative environmental project – “3D printed plastic chair reconstruction” – has attracted widespread attention. The project is promoted by an environmental organization in collaboration with the IEMAI team. By recycling waste plastics from the storage area and using on-site 3D printing to remanufacture them into public chairs, the dual goals of “waste reduction + resource regeneration” have been achieved.

1、 Waste plastic transforms into eco-friendly chairs, technology empowers green governance

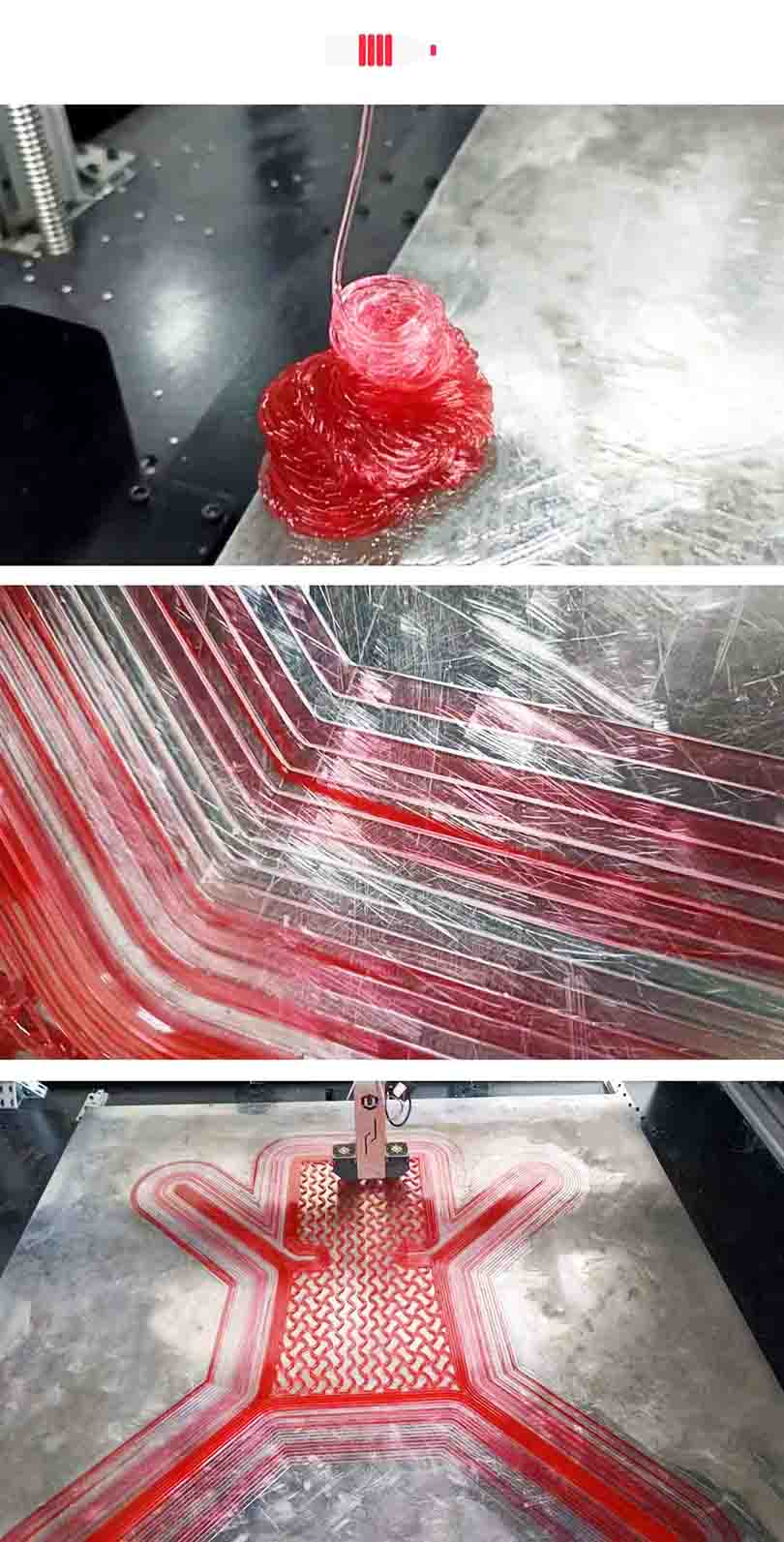

The large amount of discarded plastic bottles, fishing nets, and packaging bags collected during the cleanup operation usually need to be transported to landfill or incineration facilities for traditional disposal. And this project adopts IEMAI’s efficient particle 3D printing technology, which classifies, crushes, and melts plastic & directly prints it into sturdy and durable outdoor chairs. These chairs not only provide on-site services for tourists to rest, but also become public artworks for spreading environmental protection concepts through carving Three Gorges cultural patterns.

Waste plastics collected on-site

2、 The key steps to turning waste into treasure through 3D printing:

Recycling & sorting: cleaning plastics through classification and cleaning to remove impurities;

Crushing & granulation: specialized equipment crushes plastic into uniform particles;

Melt printing: Industrial grade 3D printers melt granular materials at high temperatures and stack them layer by layer to form them;

Low carbon & efficient: No need for molds, single chair printing only takes 2-3 hours, reducing energy consumption by 80% compared to traditional processes.

On site printing and remanufacturing of plastic chairs

3、 Environmental benefits and social value

According to project statistics, each chair consumes about 5 kg of waste plastic, and more than 50 are recycled, which is equivalent to reducing nearly 300 kg of plastic pollution. The warehouse management personnel stated that these chairs not only alleviate the pressure of garbage disposal, but also supplement public facilities, and are planned to be promoted to more scenic spots along the river in the future. Experts in environmental protection science & technology commented that the combination of 3D printing and solid waste recycling is an excellent practice of circular economy. The Three Gorges Project has verified the feasibility of on-site resource treatment and provided a useful demonstration for the treatment of Rivers & Lakes.

4、 Future prospects

IEMAI team stated that they will continue to optimize the material formula, improve the product’s UV resistance and weather resistance, and further explore the 3D printing manufacturing of functional public facilities such as garbage bins and signs, to help build a “waste free scenic area”.

Display of recycled plastic chairs

5、 IEMAI Pellet 3D Printing Solution + RECYCLE-PET Pellet Material

IEMAI relies on innovative particle direct extrusion 3D printing technology to provide revolutionary additive manufacturing solutions, which can directly transform readily available raw or recycled plastic particles (such as PP, PE, ABS, PLA, PETG, HDPE, etc.) into large and sturdy objects. There are currently 2 pellet printing solutions, FAST-JET-1500 printer and robotic printing system, which support the manufacturing of large sizes exceeding 1.5 meters and meet the needs of industries such as molds and tools; Equipped with high flow extrusion heads (3/6/20 kg/hour), intelligent temperature control, cloud control, and AI vision system. RECYCLE-PET pellet material is made of 100% post consumer recycled PET (mainly from mineral water bottles and beverage bottles), which is optimized through strict sorting, cleaning, purification, and re granulation processes. It is specially designed for direct extrusion 3D printing of granules, with high performance, low cost, and environmental protection characteristics.

Pellet 3D Printing Solution

By adopting the IEMAI Pellet 3D printing solution and RECYCLE-PET material, users can not only significantly reduce production costs, but also actively participate in the global plastic circular economy, endowing sustainable value to enterprises & individuals. Join hands to build a green and intelligent society, and jointly create a green earth home.