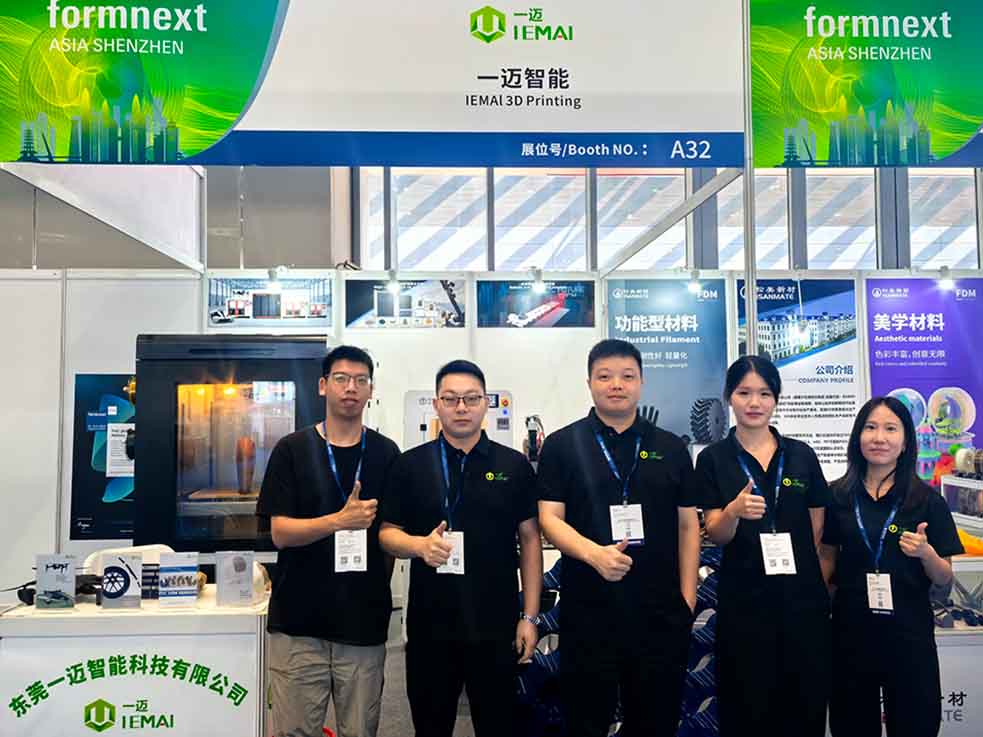

Preface: IEMAI 3D showcased its industrial grade 3D printing solutions at the Formnext Asia 2025 exhibition, demonstracting its innovative capabilities across the entire industry chain from materials, equipment to services.

On August 28, 2025, Formnext Asia Shenzhen, an international exhibition for 3D printing, additive manufacturing, and precision molding, successfully concluded at the Shenzhen International Convention and Exhibition Center. The 3 day exhibition brought together 265 industry leaders, with 131 of them participating for the first time, showcasing cutting-edge technologies and innovative applications in the field of additive manufacturing.

As a high-tech enterprise specializing in 3D printing research and production in China, IEMAI fully showcased innovative products and solutions such as high-temperature 3D printing, fiber-reinforced composite materials, and pellet extrusion systems at this exhibition, further demonstrating its technical strength and market leadership as an “all-in-one” additive manufacturing solution provider.

1、 Breakthrough in high-temperature printing technology empowers innovative applications of high-performance materials

The multi material compatible “all-in-one” 3D printing solution launched by IEMAI at the exhibition can support the vast majority of thermoplastic materials in the market, providing strong technical support for users to solve various complex needs in manufacturing production.

The MAGIC-HT-MAX and MAGIC-HT-PRO high-temperature 3D printers showcased by the company represent the advanced level of industrial grade high-temperature 3D printing technology. These machines create excellent temperature and mechanical conditions, presenting outstanding layer by layer adhesion and high-precision printing effects, providing an ideal environment for printing high-performance materials such as PEEK, PEKK, Ultem 9085/Ultem 1010, PPSU, etc., fully meeting the demanding application needs of high-end fields such as aerospace, automotive manufacturing, and petrochemicals.

High-Temperature 3D Printing Solution

High Performance Printed Parts

2、 Fiber reinforced composite material technology expands new boundaries of industry applications

At the “Fiber Reinforce Composite 3D Printing Technology & Application Forum” held concurrently with the exhibition, IEMAI showcased the innovative application achievements of short cut carbon fiber composite reinforced filament/pellets in 3D printing.

High performance carbon fiber composite filament conforms to the industry trend of “replacing steel with plastic”, demonstrating excellent mechanical performance, design freedom, functional integration, and no mold cost advantages. At present, IEMAI has accumulated rich successful cases in fields such as drone, automobile, robots, fixtures, and petrochemicals.

Carbon fiber composite pellets are oriented towards the development trend of additive & subtractive composite molds, effectively solving the industry pain points of long milling time for traditional steel molds, dependence on manual experience for wood mold production, and high steel mold costs. The company has achieved large-scale applications in fields such as automotive composite molds, ship composite molds, and aircraft composite molds.

Carbon Fiber Composite Printed Parts

3、 Innovation in pellet extrusion system, reshaping large-scale production methods

The pellet extrusion system and pellets displayed by IEMAI are important technological breakthroughs for large-scale 3D printing production. Compared with traditional wire printing, particle printing has significant advantages in the production cost and efficiency of large-sized parts.

After more than 3 years of r&d accumulation and continuous optimization iteration, IEMAI has built a complete product system including pellet extrusion system, pellet printer, robotic arm pellet 3D printing solution, and pellet raw materials. This technology is particularly suitable for fields such as furniture, construction, and molds. The company is currently developing specialized path software that is more suitable for pellet printing to further improve printing efficiency & quality levels.

4、 Deepening globalization layout & continuous increase in international market share

IEMAI actively expands its global market layout, and its products have been exported to dozens of countries and regions, while continuously improving its international sales and service network. At the Formnext Asia exhibition, numerous international clients expressed strong intentions for distribution cooperation.

The company attaches great importance to brand building and technological research and development, and has obtained trademark certificates from China, the United States, and the European Union. It also holds multiple software copyrights, invention patents, utility model patents, and design patents, and has been recognized as a national high-tech enterprise.

With the expansion of its global sales network & the continuous improvement of its brand influence, IEMAI will continue to promote the large-scale application of additive manufacturing technology in industries such as aerospace, automotive, and electronics manufacturing, providing advanced solutions for the transformation & upgrading of the manufacturing industry.

Thank you to all booth visitors for making IEMAI 3D Formnext Asia exhibition a complete success! Please continue to follow for more updates.