Preface: In the automotive industry, efficiency and precision are the core of competition. From prototype design to functional component production, traditional processes often face pain points such as long cycles, high costs, and insufficient flexibility. How to quickly respond to market demand and create high-performance, lightweight, and customized automotive parts? IDEX dual print head constant temperature industrial grade FDM 3D printer empowers intelligent automotive manufacturing with four core advantages, accelerating the implementation of innovation!

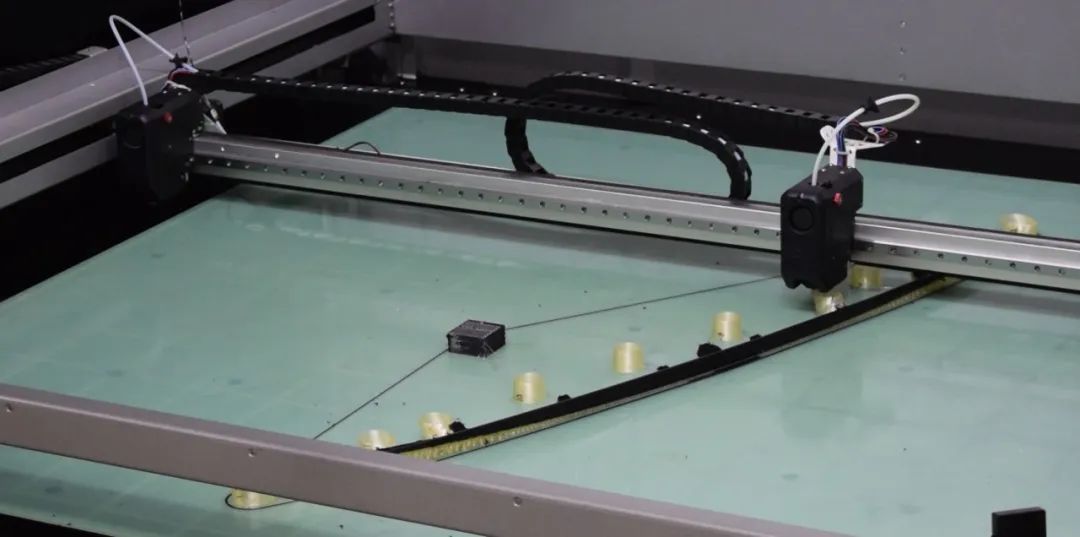

1、 Dual print head individual printing: fast support for complex structures

Pain points: Automotive parts often contain suspended and internal cavity structures, and traditional support dismantling is time-consuming and prone to surface damage.

Solution: IDEX dual print head individual extrusion system, with the main head printing high-performance engineering materials (such as nylon carbon fiber composite materials) and the secondary head synchronously printing water-soluble or easily peelable supports, saving 80% of post-processing time.

Case: Using dual head printing for car bumpers, with easy to peel support for quick removal, the surface smoothness is improved by 60%, and the production cycle is shortened to 1 day.

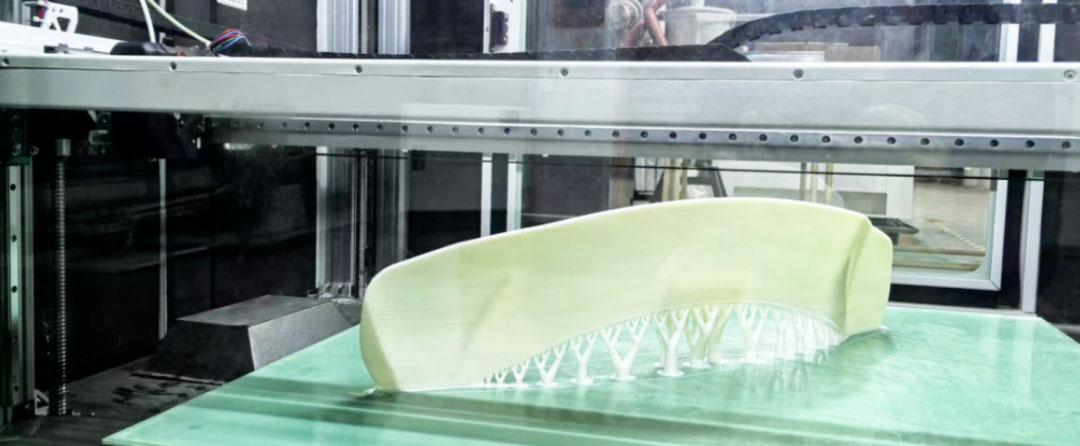

2、 Large scale integrated molding: easy implementation of large automotive components

Pain point: Traditional 3D printing equipment is limited in size, and large parts need to be assembled, which affects the structural strength.

Solution: With a large molding volume (up to 1.2 * 1.2 * 1.2 m³), it supports integrated printing of automotive interiors, lightweight body frames, pipeline gauges, and other components to avoid potential seam hazards.

High strength material compatibility: CF-PA or CF-ABS and other materials, resistant to impact and high temperature, meet the harsh environmental requirements of the automotive industry.

Case: Using YM-NT-1200 and CF-ABS, print kart functional components in one piece without splicing, reducing production cycle to 2 days.

3、 Thermostatic chamber+multi-material compatibility: stable performance, unlocking automotive grade application scenarios

Pain points: Ordinary 3D printers are prone to warping and poor interlayer adhesion, making it difficult to meet the performance requirements of automotive functional components.

Solution: Fully enclosed constant temperature chamber with a constant temperature of 60 ° C, ensuring that engineering materials such as ABS, PC, PA6, PA12 reinforced with carbon fiber or glass fiber reduce warping and achieve high-density molding.

Multi material free switching: From flexible TPU (sealing element) to high-temperature resistant CF-PPA (turbine blade prototype), it can easily meet diverse needs, and the mechanical performance of printed parts is comparable to traditional injection molded parts.

Case: Printing the rear wing of a car using high-temperature ABS.

4、 Intelligent software ecosystem: fully automated control from design to production

Pain point: Traditional printing processes rely on operational experience, have low fault tolerance, and affect mass production consistency.

Solution: The latest slicing software has built-in standard process parameters, automatically optimizes support structures and path planning, and reduces material waste by 30%.

Remote monitoring and warning: Real time monitoring of printing progress through the cloud, immediate alarm for temperature and materials abnormalities, ensuring unmanned production.

Dongguan Imai Intelligent Technology Co., Ltd is a high-tech enterprise in China focusing on 3D printing R&D and production. Its brand IEMAI 3D is a global industrial grade 3D printer brand, committed to provide users with the “All in one” 3D printing solution of multi material compatible issue. IEMAI 3D supports most of the thermoplastic materials in the 3D printing markets and assist the user to resolve the issue encounter during manufacturing, and all 3D printers and materials have achieved CE and ROHS certification. We attach great importance to brand building and have obtained trademarks certificates from China, United Sates and the European Union. We pursue core technology research and development, and have obtained software copyrights, invention patents, utility model patents, appearance design patents, and the title of national high-tech enterprise. At present, our 3D printing solutions have been applied to aerospace, automotive, petrochemical, medical and electronics manufacturing.